�

�

�

�

Eddie Beal's 1978 MGB Race Car

� Owner: Eddie Beal� � City: Lincolnton NC

� Model: 1978 MG MGB

� Built by: Huffaker Engineering

� Restored by: Acme Speed Shop�

�

As Originally Built by Huffaker Engineering...

��

Eddie Beal's MGB race car was built by Huffaker Engineering for an enthusiastic club racer named �

Don Martin. It's a replica of the Huffaker Engineering team's own British Leyland sponsored �

SCCA race cars. Huffaker MGB race cars won the SCCA E-Production national championship in �

1975, 1976, and 1977. They also finished fourth at the SCCA runoffs in 1978, but British Leyland �

had already decided their sponsorship of sports car racing would cease at the end of the 1978 �

season, so immediately after the runoffs Huffaker Engineering sold their team racecars. �

Don Martin arrived a little too late to purchase one, so Joe Huffaker Sr. suggested that his �

shop could build a brand new MGB racecar on the same pattern.�

�

Like the other Huffaker MGB's, "number 9" was built on a new old stock, early (pre-1965) MGB �

bodyshell. British Leyland specified current "production" appearance for all racecar's they sponsored, �

so after 1974 all Huffaker Engineering MGB's wore black rubber bumpers both front and rear. �

�

Don Martin raced the number 9 Huffaker MGB in regional events throughout 1979 and 1980. �

Then, Kenneth Miller purchased number 9 and raced it for one season. It passed next to a young �

racer named Danny Ross. In 1984, Hap Waldrop of South Carolina bought it for $9000, and �

raced it for four seasons. Throughout this part of its history, it was painted black. A car �

collector named Roger Mandeville purchased number 9 in 1989 for $10000, and it was retired from �

SCCA competition. Eddie Beal purchased the number 9 Huffaker MGB in 2004. He hired one of the �

car's former owners, Hap Waldrop of Acme Speed Shop to strip the car down to bare metal and do a �

complete restoration. The restoration was finished in early 2005. The car has subsequently been �

raced for four years in SVRA and HSR sanctioned vintage events.�

�

In appearance, Eddie Beal's MGB remains very true to how it looked as originally built by Huffaker �

Engineering and raced by Don Martin. For example, original paint colors were matched perfectly, �

inside and out. The distinctive single-hoop roll structure is correct, as are the fender flares. �

Huffaker Engineering still owns many of their original jigs and fixtures; they made the low �

profile windscreen (shown above) on their original mold, and provided it for the restoration. �

�

Other ex-Huffaker MGB's from the mid-seventies era still exist.¹ Generally, they've �

been updated to comply with SCCA rule changes and to remain competitive. Currently, Eddie's MGB �

most closely represents what the Huffaker Team's own British Leyland sponsored MGB's looked like at �

the height of their fame and glory. �

�

�

Enjoying this article? www.BritishRaceCar.com is partially funded through generous support from readers like you!

�

To contribute to our operating budget, please click here and follow the instructions.

�

(Suggested contribution is twenty bucks per year. Feel free to give more!)�

�

Even vintage racing requires some updates. Some of the most obvious updates to number 9 are driver �

comfort and safety related equipment such as the steering wheel, driver seat, safety harness, mirrors, �

and fire suppression system. There are also rules to keep racing affordable and competitive.�

The Huffaker team ran their MGB race cars on very low and wide racing slicks, whereas treaded �

"street" tires are usually required for MGB cars in vintage racing. Huffaker used distinctive �

custom air dams under the front bumpers of their team's race cars, but they're explicitly �

forbidden now. As shown above, a different panel has been installed under the bumper to fill �

in the gap. �

�

After we photographed Eddie Beal's MGB at the 2009 Heacock Classic Gold Cup Race, at Virginia �

International Raceway, we showed Joe Huffaker our photos. We wanted insight into the thought�

and development that went into Huffaker Engineering's original mid-seventies MGB race cars. �

Eddie's MGB represents a whole different era of SCCA E-Production racing than we've previously �

showcased. Our photo captions (below) are largely based on Joe Huffaker's comments. Since we're �

also interested in how Eddie's car has evolved over the last thirty years, we've included notes �

about that in the captions too.�

�

�

�

�

�

Features and Specifications

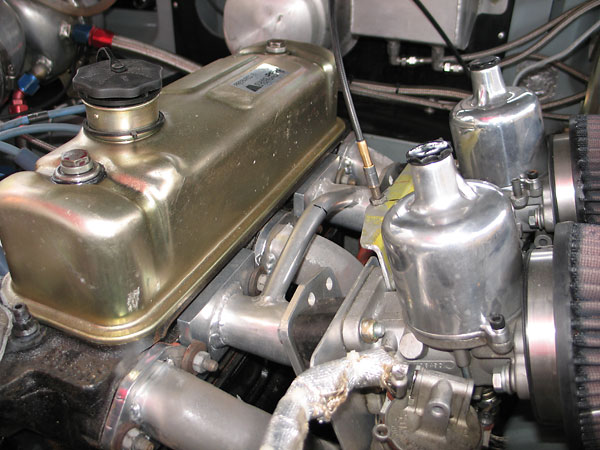

�| Engine: | �BMC B-Series 1840cc (0.047" overbore, ~12:1 compression ratio.), prepared by Midwest Motorsports.²�

Carrillo connecting rods.�

Midwest Motorsports camshaft with steel lifters. �

Midwest Motorsports prepared cylinder head.�

Maniflow tubular steel intake manifold.�

Dual S.U. HS6 (1.75") carburetors with K&N gauze air filters. �

Stock Lucas distributor with Pertronix Ignitor breakerless module.�

MSD-6A capacitive discharge ignition controller.�

Mallory ignition coil. �

Wet sump lubrication system, with Huffaker Engineering deep sump oil pan. �

Accusump oil accumulator. | �

| Cooling: | �original Huffaker brass radiator. | �

| Exhaust: | �original Huffaker long center branch 3-into-1 header. Huffaker oval megaphone muffler. | �

| Transmission: | �Quaife Rocket 4-speed dog-ring transmission. �

Lightened steel flywheel.�

Tilton 7.25" pressure plate and clutch.�

Lockheed clutch master cylinder.�

Tilton annular throw-out bearing (a.k.a. hydraulic throw-out bearing.) | �

| Rear Axle: | �modified early-model MGB "banjo" axle housing (with Salisbury style bearings/hubs).�

Tran-X limited slip differential. Choice of gear ratios. | �

| Front Susp.: | �stock MGB, except with higher rate springs, dropped spindles, and steering connections modified �

to correct bump steer. Re-valved Armstrong lever action shock absorbers.�

Uprated, adjustable anti-sway bar mounted on aluminum pillow blocks. | �

| Rear Susp.: | �three-link rear suspension plus Panhard rod, utilizing (6-leaf) leaf springs. �

Carrera steel tube telescoping shock absorbers. �

Custom adjustable anti-sway bar. | �

| Brakes: | �(master) dual Girling master cylinders with bias bar and custom remote reservoir. � (front) stock MGB. � (rear) stock MGB. | �

| Wheels/Tires: | �Minilite "SportStyle" 14x6 aluminum wheels with Hoosier "Street T.D." P205/60D14 bias ply tires. �

(When we photographed the car, it was on its spare set of wheels. It usually races on lighter�

weight three-piece Jongbloed modular wheels.) | �

| Electrical: | �Optima red battery. �

(No charging system) | �

| Instruments: | �(left to right)�

Stewart Warner water temperature (100-265F), �

Stewart Warner fuel pressure (0-10psi),�

AutoMeter Sport-Comp tachometer (0-8000rpm),�

Stewart Warner oil pressure (5-100psi), and �

Stewart Warner oil temperature (140-325F). | �

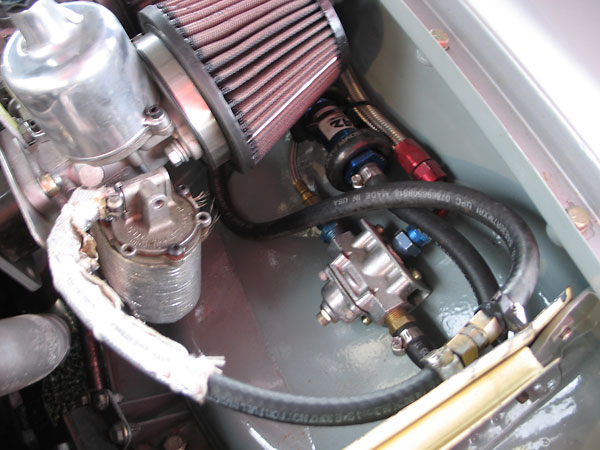

| Fuel System: | �ATL fuel cell. �

Dual Carter fuel pumps. �

Jaz Products fuel filter.�

Holley fuel pressure regulator. | �

| Safety Eqmt.: | �ButlerBuilt aluminum seat. �

Teamtech Motorsports Equipment safety harness.�

Safecraft Model RS centralized Halon fire suppression system.�

Personal anatomical, padded, black suede steering wheel on tilting/telescoping steering column. | �

| Weight: | �~1900#. | �

| Racing Class: | �originally SCCA "E Production". Currently SVRA "3DP". | �

Exterior

��

�

Huffaker Engineering was sponsored by British Leyland as they campaigned MGB race cars

�

in national level Sports Car Club of America (SCCA) races through the mid-1970's.

�

�

Huffaker Engineering traditionally painted their team's racecars black, with undercarriage and interior

�

painted dove gray. British Leyland had other ideas, and specified metallic silver for the Huffaker MGB's

�

of 1975 through 1978. The colors on Eddie Beal's MGB racecar are absolutely authentic to how

�

Huffaker Engineering originally painted the number car 9 car and also the number 11 car it resembled.

�

�

Air inlet for brake cooling duct (shown temporarily blocked due to wet racing conditions.)

�

�

Huffaker's distinctive fender flares historically came in two different sizes. The earlier style was

�

noticeably smaller than these. It was used on the Huffaker team cars through about 1974. The original

�

tooling still exists and flare kits are available from Steve Lilves (a former Huffaker employee.) The

�

larger size flares are still available directly from Huffaker Engineering, and they also offer complete

�

fiberglass replacement front fenders with integral flares.

�

�

This appears to be a SPA Design mirror. Back in the 70's, Huffaker used Vitaloni "Sebring"

�

style mirrors, mounted flat to fabricated aluminum brackets.

�

�

Pull handle doors were used on MGB's until April 1965.

�

�

"EP" is painted on the side because this car formerly competed in SCCA's E Production class.

�

�

In the mid-seventies, British Leyland's sponsorship agreement required that Huffaker team cars wear

�

black rubber bumpers, front and rear, to resemble the way MGB cars were built and sold at that time.

�

SVRA doesn't currently have an appropriate racing class for mid-seventies era SCCA race cars. Their

�

group 3, class DP rules explicitly forbid rubber bumpers, flared fenders, and air dams for the MGB model

�

because these features are representative of a more modern era than SVRA races are intended to show.

�

(A separate, additional group and class for seventies era sports cars would welcome more participants

�

and might bring literally hundreds of SCCA race cars out of barns.) However, in apparent recognition of

�

this particular car's unique provenance, SVRA has made many special allowances to permit it to race.

�

�

These Minilite "SportStyle" 14" by 6" aluminum wheels are an excellent 1960's era wheel. However,

�

in the 1970's Huffaker Engineering usually raced on 7" wide Cromodora (Italian) magnesium wheels.

�

Cromodora Wheels S.p.A. is still in business, but their older wheel models are hard to find.

�

�

Hoosier "Street T.D." P205/60D14 bias ply tires don't seem to fill the number 9 Huffaker MGB's fender

�

flares because the flares were designed to suit the wider racing slicks of later SCCA E-Production racing.

�

In an effort to keep racing relatively affordable and competitive, current vintage racing organizations

�

tightly restrict tire choices, and wide slicks aren't allowed for MGB's competing in SVRA's 3DP class.

�

�

Interior

��

�

ButlerBuilt aluminum seat. (The original racing seat would have been a fiberglass low-back model.)

�

Teamtech Motorsports Equipment safety harness.

�

�

Personal anatomical, padded, black suede steering wheel.

�

�

Huffaker MGB's were fitted with custom-fabricated, adjustably telescoping steering columns. However, the

�

original Huffaker design featured a solid inner bar that extending further rearward toward the steering wheel.

�

�

Stewart Warner water temperature (100-265F) and fuel pressure (0-10psi) gauges.

�

�

Stewart Warner oil pressure (5-100psi) and oil temperature (140-325F) gauges.

�

�

The SPA Design convex sports car mirror is a relatively new addition to the car.

�

�

This is the same type of emergency kill switch Huffaker used (from Joseph Pollak Corporation, Boston MA.)

�

�

"Three-synchro" transmission tunnel indicates conclusively that this is a Mk1 MGB bodyshell. (Early model

�

MGB bodies were lightest, and are therefore more desirable for racing.) The large, white nylon shifter knob on a

�

straight stalk is the only outward clue that the BMC 4-speed has been replaced with a modern Quaife 4-speed.

�

This quick shifting dog-ring type gearbox is a big performance upgrade; probably worth about 2 seconds/lap.

�

�

Dead pedal. Note also the provisions for adjusting the height and angle of the steering column.

�

�

Remote panel for fuel pump, starter, and ignition switches.

�

�

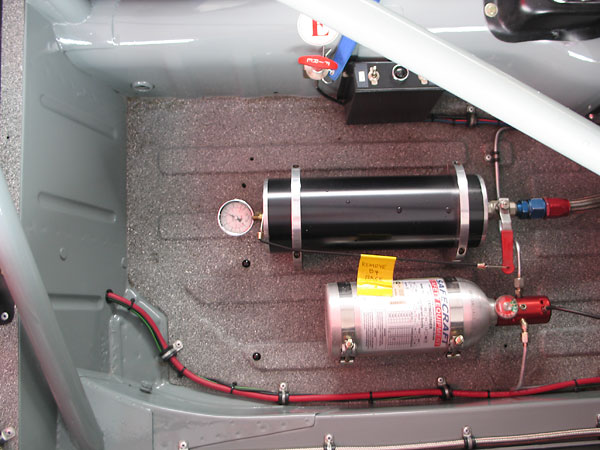

An Accusump oil accumulator (as shown at top) stores pressurized engine oil so it can be released to

�

pre-lube the engine before start-up. Accusump systems became popular in the 1980's. Although they're

�

not an authentic period feature, they're very popular in vintage sports car racing because they extend

�

engine life. The other bottle is part of the Safecraft Model RS centralized Halon fire suppression system.

�

�

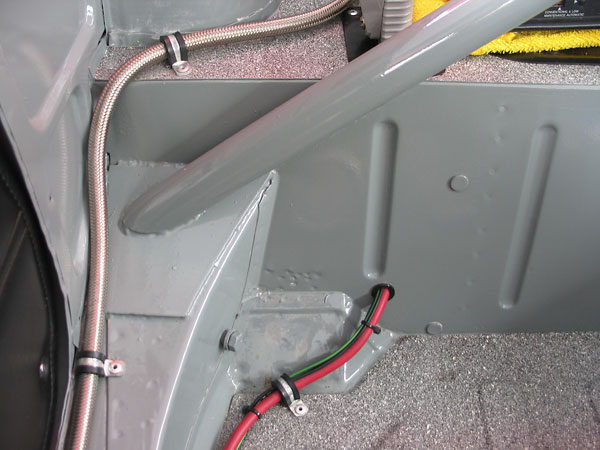

The roll structure is tied into the battery shelf and the top of the driveshaft tunnel. As you'll see below,

�

this added strength and stiffness to support one of the rear suspension's attachment points.

�

�

Another roll cage mounting detail.

�

�

The single-hoop roll structure is period correct. Later SCCA rules would mandate a more complete cage.

�

�

To get good weld penetration, it's absolutely critical that each tube be very precisely trimmed. Joe Huffaker

�

recalls that they were really fun and challenging to fabricate. He welded-up this joint on the second number

�

11 MGB, but his friend Jim Lerch got to do the job on the number 9 car. In both cases, the rollcages were

�

constructed of mild steel and all the joints were TIG welded.

�

�

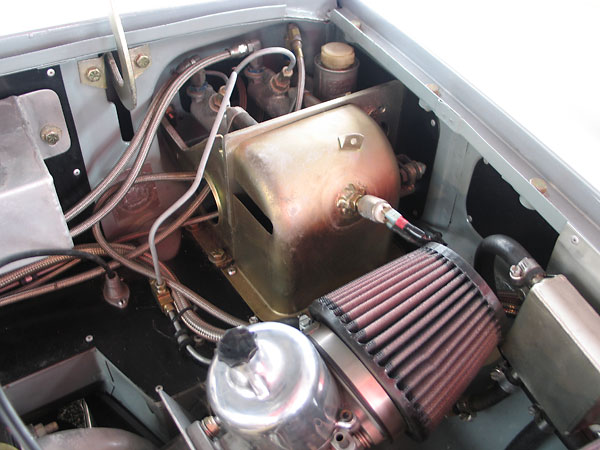

Engine Installation

��

�

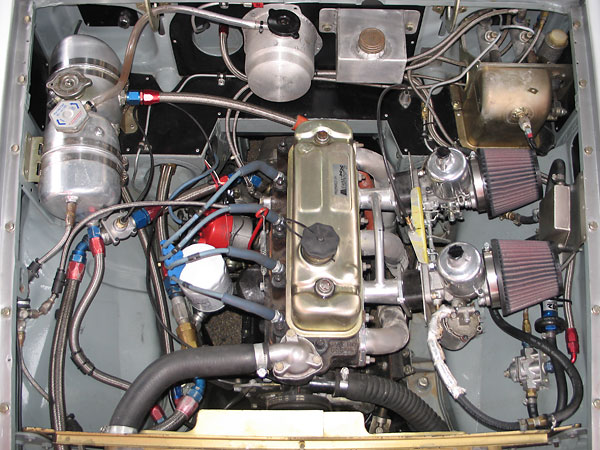

Many aspects of the number 9 Huffaker MGB replicate how the number 11 car was raced, but not engine

�

compartment plumbing. As Joe Huffaker recalls, the Huffaker team cars had far fewer hoses and connections.

�

�

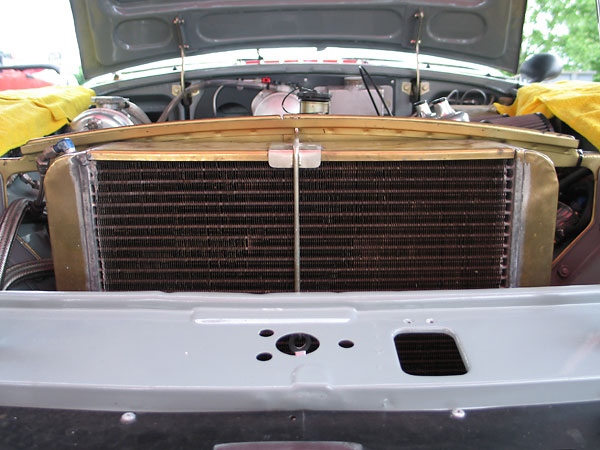

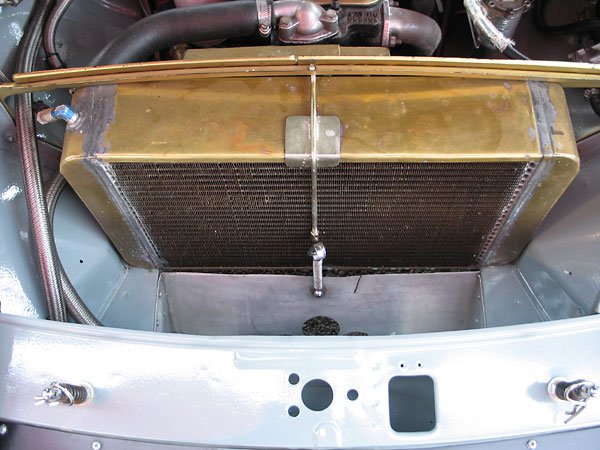

Brass radiators were a Huffaker trademark. They were made to Huffaker specifications by a small, local

�

radiator shop. These radiators weren't particularly large, but they had thick cores. In the mid-1970's,

�

aluminum radiators weren't nearly as readily available as they are today.

�

�

Another Huffaker Engineering trick is that the radiators were clamped down with spring-clips,

�

so when service is required they can be removed in minutes.

�

�

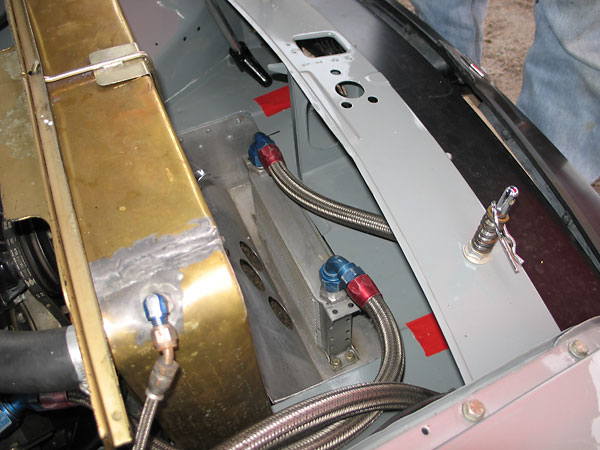

The aluminum oil cooler shelf is believed to be original to the number 9 Huffaker, but it's a different

�

design from earlier Huffaker team cars. The three chassis-punched holes behind the cooler are newer.

�

�

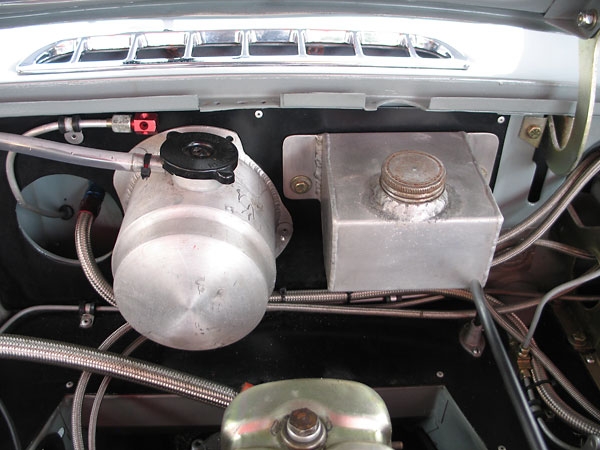

Huffaker used Harrison aluminum coolant header tanks with Stant pressure caps (as shown at left.)

�

The oil system breather tank (with vent holes drilled in its cap) is believed original to the number 9 car.

�

An in-line oil temperature sensor fitting is below the header tank. Note also that the ignition coil

�

has been relocated into the passenger-side footwell, which is a good idea since that keeps it cooler.

�

�

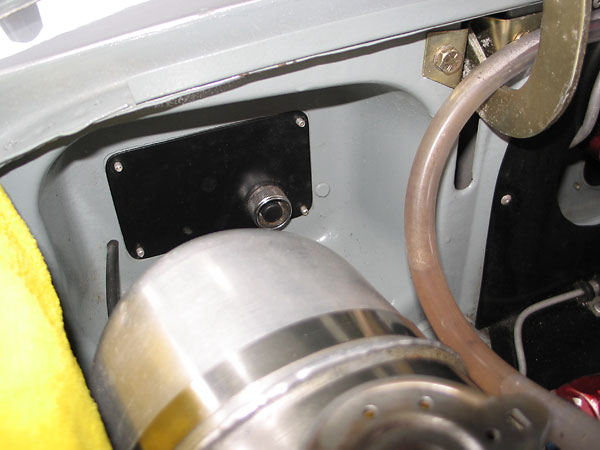

Remote starter switch.

�

�

Coolant overflow tank (at left, not a period feature) and brake system fluid reservoir (right). This photo

�

also shows a subtle demon tweak: Huffaker didn't block heater fan holes. Since the car doesn't have a

�

steep windshield, the chromed cowl vent is in a low pressure area at speed. Venting air out at the cowl

�

slightly reduces overall wind resistance and significantly reduces engine compartment temperature.

�

�

Dual Girling master cylinders with adjustable bias bar, and Lockheed clutch slave cylinder.

�

(The pedal box cover is slotted for more convenient access to the bias bar.)

�

�

K&N gauze air filters clamp directly to shortie velocity stacks.

�

�

Jaz Products fuel filter and Holley fuel pressure regulator.

�

�

Note the Midwest Motorsports decal on the valve cover, and the Maniflow fabricated intake manifold.

�

�

Although a flat aluminum heat shield is installed between carburetors and intake manifold, heat

�

reflective fabric has also been wrapped around the forward fuel line and carburetor float bowl.

�

�

Front Suspension

��

�

Uprated, adjustable anti-sway bar mounted on aluminum pillow blocks. Spacers between the steering links

�

and arms (where Heim joints are being used in lieu of tie rod ends) have been installed to adjust bump steer.

�

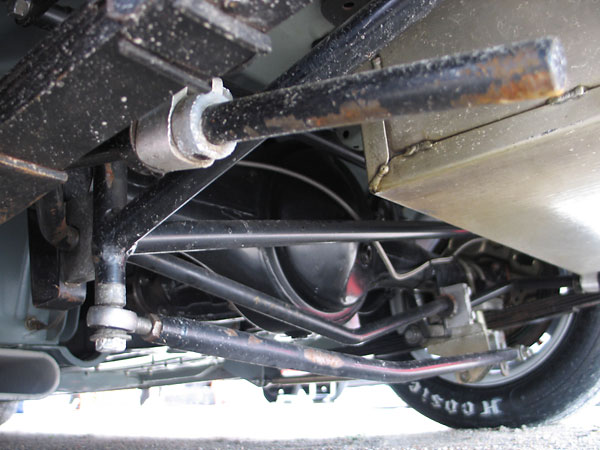

Rear Suspension

��

�

Don't be fooled by confusing terminology or by the appearance of leafsprings: this is in fact what racers

�

call a "three link" rear suspension. Unlike a stock MGB, these leafsprings DON'T serve to locate the

�

rear axle longitudinally or laterally. There are three trailing links from the bodyshell rearward to the axle

�

housing for longitudinal location, supplemented by a Panhard rod for lateral location. For this approach

�

to work without binding, it's critical that the rear axle can float freely relative to the springs.

�

�

The U-bolts don't clamp tightly to the leafsprings because spacer tubes have been installed between

�

spring perches and the lower spring plates. In this view you also see where the Panhard rod connects.

�

�

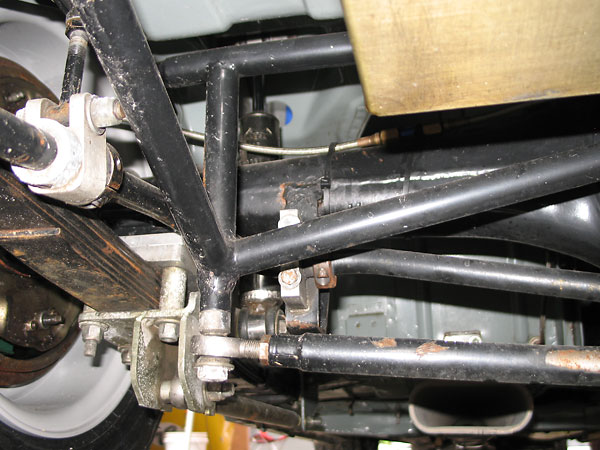

This photo shows the two types of trailing links: two links under the leafsprings plus one above the

�

differential housing running forward to a mounting plate next to the driveshaft tunnel. The center

�

trailing link can be mounted at various heights because its mounting angle determines anti-squat.

�

�

Incidentally... Huffaker made their own distinctive oval megaphone mufflers, usually out of stainless steel

�

by cutting pieces of tubing lengthwise, prying them apart, and welding-in long triangles of flat material.

�

The oval shape was for ground clearance. The rolled edge at the rear helped keep the welds from splitting.

�

Megaphones seem to provide a worthwhile power boost, but they don't provide much muffling effect.

�

�

Huffaker put a lot of effort into tuning spring rates and ride height by building up their leafspring

�

packs in various configurations. (Typically, they ran very soft wheel rates at the rear.)

�

Any friction or binding in the suspension would jeopardize this careful tuning work.

�

�

Besides locating the axle laterally, the Panhard rod also determines the rear suspension's roll center.

�

Huffaker prefers a relatively low roll axis, sloping downward toward the front of the car. The Panhard rod

�

shown here isn't authentic to how Huffaker built the car. The bend in the middle is very undesirable for

�

two reasons: stiffness and ease of length adjustment. Normally, radius rods are built with oppositely

�

threaded Heim joints so that precise length adjustment can be made without disconnection of the rod,

�

by simply loosening the jam nuts, rotating the rod, and re-tightening the jam nuts. The anti-sway bar

�

is also bent in the middle, but that's an authentic feature. However, its installation isn't quite correct:

�

the arms should be parallel to the ground when the car is at static ride height.

�

�

Huffaker designed the connecting links to be free to rotate on the bar so they wouldn't bind as the

�

suspension worked. Split collar clamps can be shifted to change the effective lever length, and thus

�

adjust roll stiffness. A corresponding adjustment of the chassis connection needs to be made too.

�

�

The anti-sway bar chassis brackets have selectable connection points to keep their geometry right.

�

Connecting links should be perpindicular to the anti-sway bar when the car is at static ride height.

�

�

Anti-sway bar mounts on the rear axle housing.

�

�

Huffaker Engineering used Armstrong lever-action shock absorbers with special adjustable valves.

�

World Wide Auto Parts sells modified Armstrong shock absorbers that are similarly adjustable.

�

However, the number 9 Huffaker currently uses Carrera steel telescoping rear shock absorbers.

�

| Footnotes: | |||||||

| (1) | �

Terry Visger drove a silver number 11 Huffaker MGB to victory in the 1975 SCCA runoffs.�

That first number 11 race car was sold to Dwayne Anderson of Whittier California, and �

subsequently crashed beyond repair. Dwayne Anderson used parts from the first number 11 MGB �

to build a replacement that looked quite a lot like a Huffaker. Dwayne Anderson's �

Huffaker-inspired MGB was later driven by Lee Mueller (representing the Huffaker team) �

to a second place finish in the 1978 runoffs. At the 1978 runoffs, it was red and it �

wore number 10. Immediately after the runoffs it was sold to Chris Doyle. It's currently �

owned and raced by Don Dickey.�

� Joe Huffaker Jr. and Jim Lerch of Huffaker Engineering built up a new (i.e. second) number 11 � MGB for the 1976 season, and Terry Visger drove it to championship victory in 1976 and then again � in 1977. For the 1978 championship, Terry Visger wasn't available and driving responsibilities � instead passed to John Woodner. Woodner drove the silver number 11 Huffaker MGB to fourth � place in the E-Production championship race. Immediately after the runoffs, the number 11 � Huffaker MGB was sold to Mike Pinney who painted it red and ultimately drove it to a third � place finish at the 1981 runoffs. (At some point it has been repainted silver.) The number 11 � Huffaker MGB was then owned and raced by Don Small, who finished third at the runoffs in 1984. � It currently belongs to Rick Estes of Kansas.� � A single-seat-rollcage Huffaker MGB was built to order in the late seventies for � Dr. Gary Gienger of Waterloo Iowa. Dr. Geinger ultimately sold that car to Gerry Lamb, � who has campaigned it in SCCA events over many years.� � | ||||||

| (2) | �

Eddie Beal's MGB is currently equipped with an engine built for reliable service in vintage �

racing. He has two additional engines which were originally prepared by Huffaker Engineering, �

and which could be re-installed in the future to restore the car to a more accurate representation �

of original specification. � | ||||||

�

All photos shown here are from June 2009, when we viewed the car at The Heacock Classic Gold Cup at �

Virginia International Raceway. All photos by Curtis Jacobson for BritishRaceCar.com, copyright 2010. �

All rights reserved.

�

| If you liked this article, you'll probably also enjoy these: | �|||||

| �

David Child 1964 MG MGB | �

| �

Marcus Jones 1964 MG MGB | �

| �

Don Dickey 1965 MG MGB | �

| You're invited to discuss anything you've seen here on The British Racecar Motorsports Forum! | �|||||

�

Notice: all the articles and almost all the photos on BritishRacecar.com are by Curtis Jacobson.

�

(Photos that aren't by Curtis are explicitly credited.) Reproduction without prior written permission is prohibited.

�

Contact us to purchase images or reproduction permission. Higher resolution images are optionally available.

�

�

�