�

�

Mark Rosenberg's 1959 Peerless GT leads a Turner sports car in the Jefferson 500 at Summit Point.

�

Mark Rosenberg's 1959 Peerless GT Race Car

� Owner: Mark Rosenberg� � City: Baltimore MD

� Model: 1959 Peerless GT

� Engine: Triumph TR3/TR4 (see below)

� Originally race prepared by: Treasured Motorcars, Owings Mill MD (1990)

� Race prepared by: Merryman Modifications, Hanover PA (currently)�

�

History of Peerless Cars

��

Hotelier and restaurateur James ("Jimmy") Byrnes recruited Bernie Rodgers to design �

a racing car. Although the original goal was a one-off car for club racing, the two �

men ended up with a small car company. Things like that sometimes happen if you�

know the right people, and Jimmy Byrnes met lots of people though his restaurant.�

�

The old "Saxon Mill" restaurant in Warwick was a favorite of the Board of Directors�

of the Standard Triumph car company. Having become friends with the Board, Byrnes was �

naturally interested in utilizing Triumph parts in the proposed racecar. He �

instructed Rodgers to use Triumph TR3 components wherever they would suit. �

�

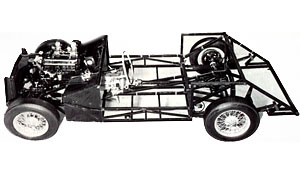

| � From very early on, Bernie Rodgers imagined that a multi-tube frame constructed � mainly of 16-gauge 1" x 1.5" rectangular steel tubing might be a very practical � basis for a small sports saloon. Byrnes commissioned an all-aluminum body, a � Triumph TR3 drivetrain was procured, and a prototype car was constructed. As the � pieces came together, the prototype was initially given the name "Warwick". � As Byrnes and Rodgers drove the Warwick and showed it to their friends, they � realized other people were interested in owning one too. They decided to test � the waters and determine if it might make sense to build a whole batch of cars.� | �� | �

� (Peerless promotional illustration)� | �

�

Byrnes showed the prototype car to an old army friend named John Gordon, who had a �

used car dealership. Gordon agreed that the prototype's performance was impressive, �

but he suggested enlarging and widening the body. This suggestion was based on his �

perspective as a car salesman, but it provided a performance benefit too, especially �

because with wider track Bernie Rodgers decided it was feasible to fit a de Dion �

suspension instead of a Triumph TR3 live axle. John Gordon joined the project team, �

and the three partners made plans for a more public testing of the market.�

�

A second aluminum bodied Warwick prototype was built and shown at the 1957 Paris �

Motor Show. You could hardly call them a company yet, but based on public reaction at �

that show the three men were already thinking of a production rate of 1500 cars per �

year. One American car dealer told them he was confident he could personally sign �

for eighty cars per month. Much more importantly, the second prototype was extremely �

well received by Jimmy Byrnes' friends on the Standard Triumph Board of Directors. �

They evidently believed that the Warwick could only embellish the prestige of their �

own products. Triumph would provide necessary components, and indeed would provide �

components at a favorably low cost. �

�

�

Enjoying this article? www.BritishRaceCar.com is partially funded through generous support from readers like you!

�

To contribute to our operating budget, please click here and follow the instructions.

�

(Suggested contribution is twenty bucks per year. Feel free to give more!)�

�

The model name change from Warwick to Peerless occurred after the entrepreneurs settled �

into a physical address. They had acquired a bankrupt car dealership upon whose �

property American-made Peerless military trucks had previously been stored and serviced, �

and they decided the name Peerless suited their own ambitions nicely. It almost goes �

without saying that they hoped to export a lot of cars to America, and they imagined �

the bold new name would help. (The Peerless company of Cleveland Ohio no longer built�

automobiles.)�

�

Due to a lack of funds for press tooling, the newly formed Peerless Cars Limited decided �

to use fiberglass for production bodies. This was a gamble because at the time there �

were no well-known fiberglass cars in the British marketplace. Indeed, the only �

"mass produced" fiberglass passenger car in the world was the Chevrolet Corvette. �

(The Daimler SP250 was being developed �

and introduced at almost the exact same time as the Peerless GT. A few other small-scale �

and specialty manufacturers like Turner �

seemed to be having good success with fiberglass.) If customers were risk averse, �

fiberglass might be a turn-off. Would it be durable? How would it weather and age? �

The new material would present new technical and manufacturing challenges too, but �

this was a brand new company that would be learning its way in any case.�

�

�

�

Peerless Cars, GT, 2 Litre, Slough England.

�

�

Peerless hired a local coachbuilding company named James Whitson Ltd. to produce�

their fiberglass bodies. Initial cost was acceptable; and fit and finish seemed �

adequate. �

�

To prove their new car, the company entered a Peerless GT in the 1958 24 Hours of �

LeMans race. Peter Joppe and Percy Crabb drove the British Racing Green number �

"24" car to 16th place overall and 4th place in the two liter Sports class. The team �

only made scheduled pit stops, and they lost just seven minutes to downtime. They �

kept up a brisk pace too, averaging 83.6mph despite many hours of rain and at least �

one period of torrential downpour, to complete 240 laps and a total distance of over �

2006 miles. Incidentally the Peerless was the only Triumph-powered car entered;�

racing success for Peerless was seen as very good publicity for Triumph.�

�

At this stage in the company's life, sales weren't a problem. They couldn't build cars �

fast enough. Their main difficulty was that fiberglass construction is labor intensive. �

It's hard to rush production without investing in more moulds and more operators. �

After about 250 cars had been produced, Peerless decided to revise the body design to �

incorporate many improvements, and simultaneously to transfer their supply agreement �

from James Whitson Ltd. to a company named Wincanton Transport and Engineering Company. �

The Phase One and Phase Two bodies look quite similar, but in fact the manufacturing �

processes that created them were very different. During Phase One construction, 57 �

different molded parts were bonded together to create a bodyshell that was then bonded �

and pop-riveted to the tubular steel chassis. In contrast to that, each Phase Two �

bodyshell was constructed as a single elaborate part created in a large, very �

elaborate, multi-section mould. The mould held panels aligned as the structure became �

increasingly complete, stiff, and strong. Phase two bodyshells were bolted (removeably)�

to the tubular steel chassis. �

�

Regrettably, there isn't a whole lot more to tell about Peerless Cars Ltd. The company �

principals had a falling out. John Gordon left, and with him Peerless lost its �

principle salesman and promoter. He would later join forces with Jim Keeble to form �

Gordon-Keeble Cars Ltd. About a hundred small block Chevy powered Gordon-Keeble cars �

were produced between 1963 and 1966. Bernie Rodgers and Jimmy Byrnes salvaged the remains �

of Peerless Cars Ltd. by forming a new company and continuing production on a smaller �

scale. They reverted to the original model name: Warwick. About forty Warwick GT's �

were built, some with marvelous Buick 215 aluminum V8 engine (which was notably lighter�

weight and fifty-five percent more powerful), before the company folded in 1962. �

�

�

�

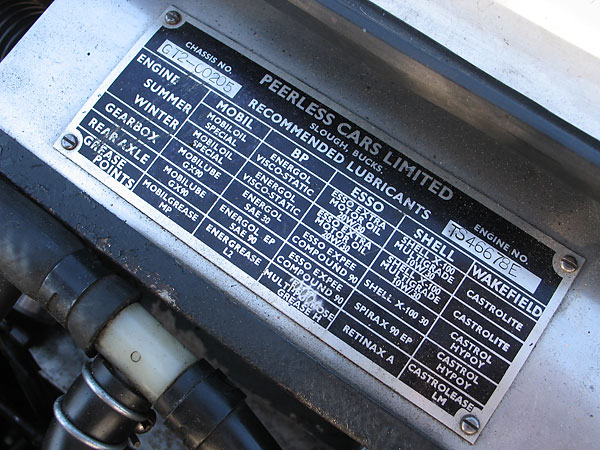

Peerless Cars Limited, Slough, Buckinghamshire

�

Chassis No. GT2-00205, Engine No. TS46678E

�

Mark Rosenberg's Peerless GT (Phase One)

��

Mark's Peerless GT is number 205 of 325 produced. It's one of approximately seventy�

left-hand-drive Peerless cars which were exported to the United States. �

�

The car was originally set-up for racing by John ("Jake") Jacobson of Old Spokes �

Vintage Racing of Newark Delaware in 1990. Since April 1991, Mark has driven it in �

35 events including seven Pittsburg Vintage Grand Prix appearances and seven Jefferson �

500 appearances. �

�

Mark's Peerless is maintained, race prepared, and gradually refined by Jack Merryman of �

Merryman Modifications in Hanover Pennsylvania, and by Geoffrey Griffiths of �

Treasured Motorcars of Owings Mills, Maryland. �

�

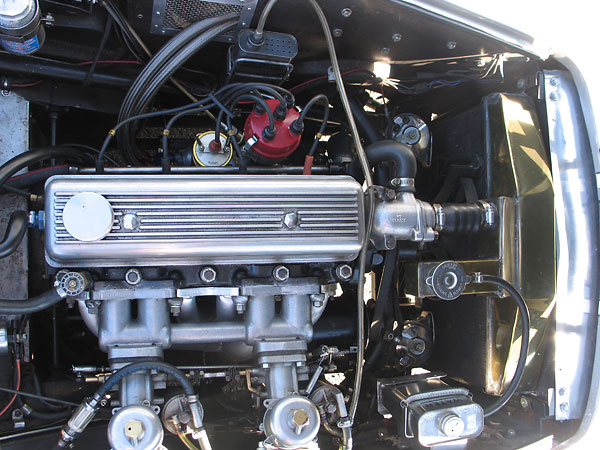

Peerless GT's were originally built with stock Triumph TR3 engines, which had 83mm bore �

wet cylinder liners, and a total displacement of 1991cc. Mark's engine has been re-sleeved �

to 86mm for a displacement of about 2138cc, which is nominally the same as a Triumph TR4. �

Many other modifications have been made for racing, as described in more detail below. �

On the chassis dyno for tuning, the engine pulls about 130bhp.�

�

�

�

�

�

Features and Specifications

�| Engine: | �rebuilt with larger cylinder sleeves (86mm in lieu of 83mm.)�

Billet connecting rods. Aluminum racing pistons. �

Ported big-valve cylinder head, milled to unshroud the valves and �

increase compression ratio. (Static compression ratio is ~10:1.)�

Double valve springs. Titanium collars and keepers.�

Chrome moly pushrods. Lightened and hardened tappets.�

Camcraft nitrided race camshaft.�

Dual S.U. 1.75" carburetors.�

Mallory dual point distributor.�

Lucas Sport ignition coil. �

Packard 440 (7mm copper core) spark plug wires.�

Competition oil pump with Ford V8 pick-up. �

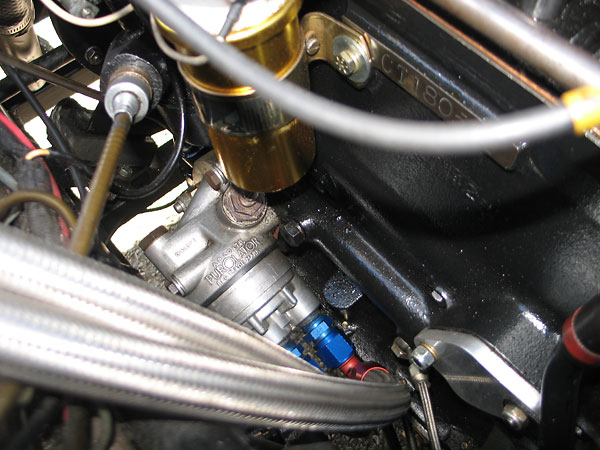

Purolator adapter for spin-on oil filter, connects to a spin-on oil cooler adapter.�

Oil cooler. Remotely mounted (Pennzoil PZ-34) oil filter. �

| �

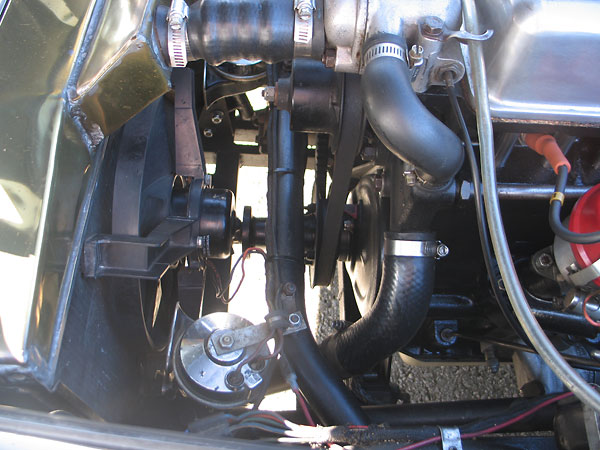

| Cooling: | �custom 5-row copper/brass radiator.�

Electric cooling fan. | �

| Exhaust: | �Triumph TR3 tri-Y (4-2-1) header, modified to fit, feeding to open exhaust. | �

| Transmission: | �Triumph TR4 4-speed (without overdrive).�

Centerforce clutch. � Lightened TR4 flywheel.� Driveshaft rebuilt with Volvo yokes, etc. | �

| Rear End: | �Salisbury open differential with 3.7:1 gear ratio. | �

| Front Susp.: | �Triumph TR3 derived dual wishbone front suspension with Cam Gears worm �

and peg steering box, upgraded with SPAX shock absorbers and oversized �

front anti-sway bar mounted on aluminum pillow blocks. | �

| Rear Susp.: | �stock de Dion tube located on custom semi-elliptic leaf springs. �

Armstrong lever shock absorbers, upgraded with race valving. | �

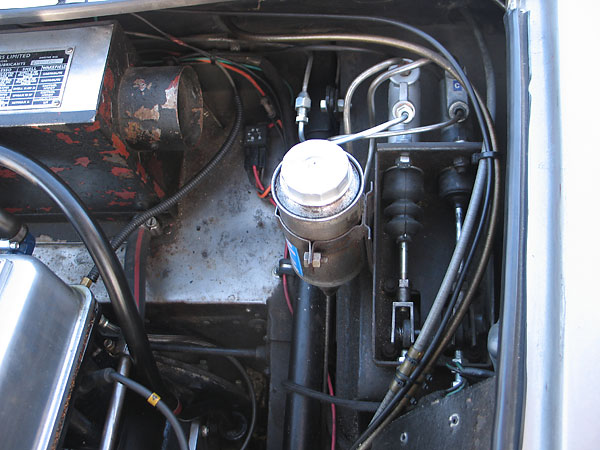

| Brakes: | �(master) single Girling remote-reservoir master cylinder. � (front) 10.75" Brembo rotors. Carbotech carbon fiber brake pads. � (rear) 10" drums. | �

| Wheels/Tires: | �Dunlop 15x4.5" 60-spoke wire wheels. Dunlop Racing tires (5.50L15). | �

| Electrical: | �Lucas generator.�

12V lead acid battery.�

Lucas windshield wiper system. �

Dual electric horns. | �

| Instruments: | �Jaeger speedometer and mechanically driven tachometer.�

Smiths ammeter and fuel level gauge (not used). � Stewart Warner coolant temperature and oil pressure gauges. | �

| Fuel System: | �Fuel Safe 12 gallon fuel cell.�

Facet solid state fuel pump. | �

| Safety Eqmt: | �5-point roll structure.�

Kirkey aluminum racing seat (16", 41500V). � Simpson latch-and-link harness.� Wink wide view mirror. | �

| Weight: | �~2400 pounds. | �

| Racing Class: | �over two litre, production. | �

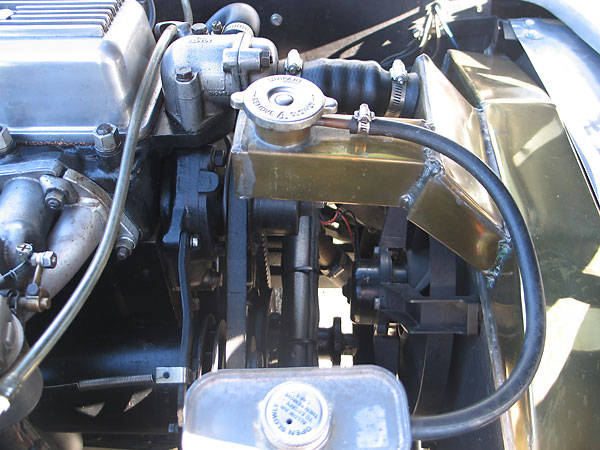

Engine Installation

��

�

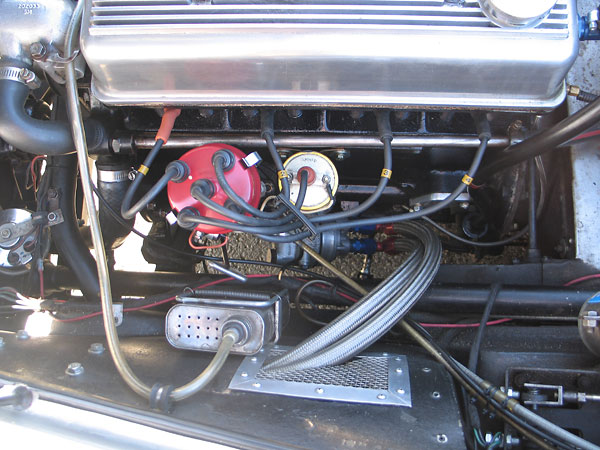

Triumph TR3 engine, rebuilt with larger cylinder sleeves (86mm in lieu of 83mm).

�

�

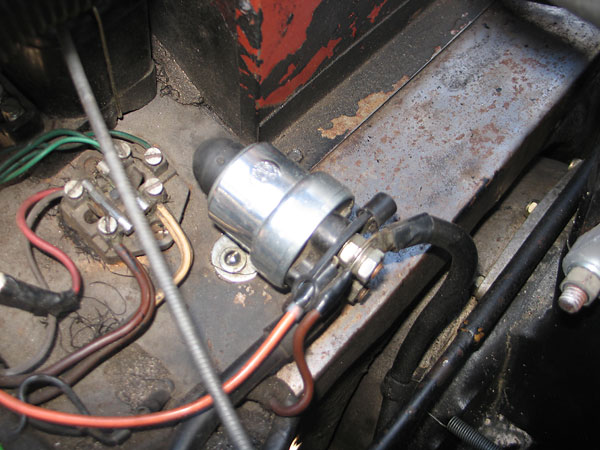

Single Girling remote-reservoir brake master cylinder.

�

�

The Lucas windshield wiper system remains in place. Good windshield wipers were critical to the

�

success of Peerless in the 1958 24 hours of LeMans race.

�

�

Oil cooler plumbing.

�

�

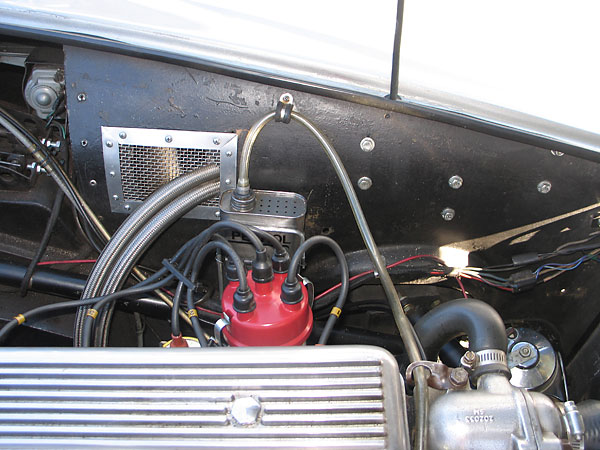

Mallory dual point distributor. Lucas Sport ignition coil.

�

�

The cable for the mechanical tachometer connects at the base of the distributor, driven off the camshaft.

�

It's never given any problems. The Triumph engine also has provisions for a camshaft driven fuel pump,

�

although the Peerless came with dual S.U. electric pumps instead. Notice the stainless steel braided

�

hose that's connected to an oil galley a couple inches below the fuel pump blockoff plate. It was added

�

to provide supplemental lubrication to the valvetrain.

�

�

Electric cooling fan and dual electric horns.

�

�

Thermostat housing.

�

�

Left: Lucas generator. Right: generously sized custom 5-row radiator and electric cooling fan.

�

�

Triumph intake manifold and exhaust header flanges.

�

�

Dual S.U. 1.75" carburetors.

�

�

Remote starter switch.

�

�

Remotely mounted (Pennzoil PZ-34) oil filter, and oil cooler connections.

�

�

Front Suspension

��

�

Triumph TR3 dual wishbone front suspension, upgraded with SPAX shock absorbers.

�

(The shock absorbers can't easily be seen because they're inside the coil springs.)

�

�

Oversized front anti-sway bar mounted on aluminum pillow blocks.

�

�

Details of the Peerless chassis, and also the long secondaries of the tri-Y header.

�

(The Triumph TR3 header had to be modified to fit the Peerless.)

�

Rear Suspension

��

�

The Salisbury differential is mounted rigidly to the Peerless GT chassis.

�

�

Mark discovered that replacement Triumph TR3 leafsprings won't fit on the Peerless GT. Instead, he

�

needed to have custom springs made. After a lot of trial and error he found that this softer, flatter

�

two-leaf spring worked best. His lever-arm rear shock absorbers have also been custom tuned.

�

�

The de Dion tube which connects the rear hubs is just visible behind the telescoping halfshafts.

�

�

Interior

��

�

In the 1950's and early 60's it was sometimes considered unsporting to strip interior trim from a racecar.

�

Mark Rosenberg's Peerless GT includes a horseshoe for good luck, screwed down within driver's sight.

�

�

Jaeger speedometer and mechanically driven tachometer. Smiths ammeter and fuel level gauge (not used).

�

Stewart Warner coolant temperature and oil pressure gauges.

�

�

The Paddy Hopkirk style throttle pedal is connected to the carburetors through a mechanical linkage.

�

(Incidentally, the choke is also worked by a linkage instead of a cable.) The original foot-operated

�

headlight dimmer switch has been relocated away from the pedals and can be seen here in the upper,

�

lefthand corner of the photo. Next to it, a vacuum switch controls the windshield washer system!

�

�

Kirkey aluminum racing seat (16", 41500V). The back seat has been removed to reduce weight. Now,

�

quickly removeable panels facilitate convenient access to the differential and rear suspension.

�

�

Peerless adapted a Rolls Royce window regulator mechanism. Instead of having a crank (with gears), the

�

window lift is simply a lever that moves between twelve o'clock and three o'clock positions. It works great!

�

The window rises quickly and smoothly. Notice driver Brian Redman's autograph above the door window.

�

Dickie Attwood's autograph is written above the driver's side door window.

�

�

Fuel Safe 12 gallon fuel cell.

�

�

Exterior

��

�

�

After creating two aluminum prototypes, all production Peerless GT's had fiberglass bodies.

�

�

The biggest difference between the ~250 Phase One bodies and the ~75 Phase Two bodies was how they

�

were made. However, the later fabrication techniques did result in a shell that was lighter and stiffer.

�

Underneath, the steel frame wasn't changed between Phase One and Two. It weighed just 123#.

�

�

For racing, the original sylized-"P" radiator trim has been removed from Mark's Peerless GT.

�

(Phase Two cars would be fitted with recessed grille.)

�

�

The narrow A-pillars that frame the sides of the windshield are great in terms of visibility, but

�

they're one of the most fragile and crack prone parts of the fiberglass Peerless GT bodyshell.

�

Incidentally, the Peerless GT windshield is identical to a Morris Minor rear window.

�

�

Aside from the body, frame, soft interior trim, and de Dion tube, very few parts of the Peerless GT were

�

designed specifically for or by Peerless. The taillights Peerless used, for example, were also used on

�

the Bentley Continental S1, Humber Super Snipe (some years), Aston Martin DB4 and Alvis TD 21. The

�

license plate lamp was used by Rover and Jaguar. The rear window, however, seems to be unique.

�

�

With Phase Two the door, bonnet, and boot hinges were all modified to include automatic stops...

�

�

... and a single offset blister would replace the original bonnet "double-hump".

�

�

Mirrors.

�

�

The passenger side fuel filler has been removed and replaced with an emergency engine "kill" switch.

�

Old Spokes Vintage Racing Team window decal.

�

�

The driver side fuel filler has beem safety wired shut, although it's not connected to a fuel tank.

�

The Peerless GT originally came with dual fuel tanks, with a total capacity of 14 Imperial gallons,

�

and dual S.U. electric fuel pumps. The whole system was removed, for a significant weight reduction.

�

�

Dunlop 15x4.5 60-spoke wire wheels with Dunlop Racing tires (5.50L15).

�

�

Wider wheels and tires would easily fit, but they're forbidden under the

�

Vintage Sports Car Club of America (VSCCA) rules that apply to the Peerless GT.

�

�

Except for the very first two photos above, all photos shown here are from November 2009 when we �

viewed the car at VRG's Turkey Bowl at Summit Point Motorsports Park, West Virginia. �

Photos by Curtis Jacobson for BritishRaceCar.com, copyright 2009. All rights reserved. �

The photo of Mark racing in the Jefferson 500 was provided by Mark, and has been published �

by exclusive permission. The original Peerless Cars Ltd. illustration is a period �

promotional photo, used under "fair use" guidelines.

�

| If you liked this article, you'll probably also enjoy these: | �|||||

| �

Tivvy Shenton '55 Jaguar XK140 FHC | �

| �

Joe Dockman '60 Daimler SP250 | �

| �

George Wright '61 Triumph TR4 | �

| You're invited to discuss anything you've seen here on The British Racecar Motorsports Forum! | �|||||

�

Notice: all the articles and almost all the photos on BritishRacecar.com are by Curtis Jacobson.

�

(Photos that aren't by Curtis are explicitly credited.) Reproduction without prior written permission is prohibited.

�

Contact us to purchase images or reproduction permission. Higher resolution images are optionally available.

�

�

�